Optimizing Data Center Cooling with STAR-CCM+ and TotalSim Expertise

The Situation:

In an era where digital infrastructure is vital, data centers have become the heart of business operations—powering everything from cloud computing to mission-critical analytics. Ensuring their reliability and minimizing downtime is paramount. TotalSim was brought in to support a building services and construction contractor, alongside their design partner, in bidding for a state-of-the-art data center project. The goal: to validate and enhance HVAC performance through advanced simulation.

Client Challenge:

Modern data centers generate intense heat loads, making efficient thermal management a cornerstone of their design. The client needed to ensure that even under partial HVAC failure, sensitive zones within the facility would remain below critical temperature thresholds. This required a highly optimized and fault-tolerant cooling strategy.

Type of TotalSim Engagement:

TotalSim was engaged to simulate, analyze, and improve the airflow and thermal performance of the proposed data center layout using advanced computational fluid dynamics (CFD) tools.

Approach & Solution:

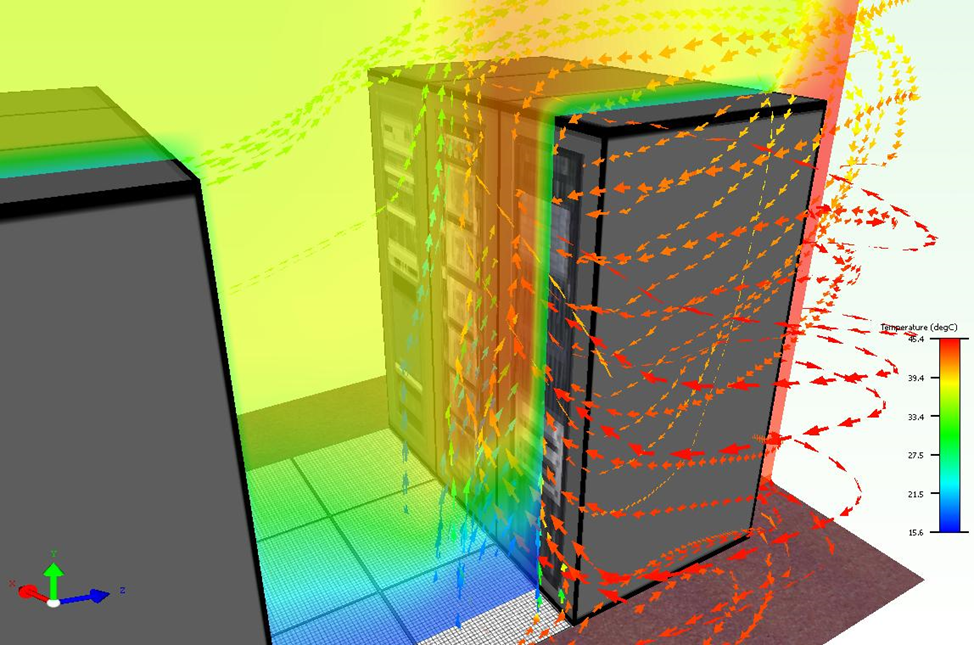

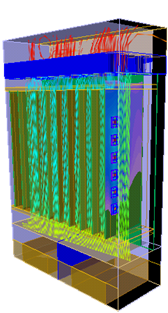

1. Accurate Thermal Modeling with STAR-CCM+

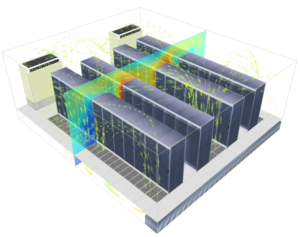

Beginning with the initial architectural design, TotalSim modeled the airflow patterns within the enclosure, paying close attention to the hardware exhaust geometry and potential flow obstructions. Using Siemens STAR-CCM+, we simulated a variety of configurations to ensure temperatures throughout the space remained within safe limits—even under partial system failure scenarios.

2. Failure Mode Analysis

We conducted a comprehensive failure analysis, simulating scenarios where individual HVAC units were turned off. This helped identify high-risk zones and evaluate the robustness of the design. In these simulations, we explored how adjusting the vane angles of each HVAC unit could redirect airflow to better target hot spots.

3. Acoustic Performance

In addition to thermal modeling, we utilized Siemens Ray Acoustics Modeling to analyze noise propagation from hardware fans. This insight helped ensure acoustic comfort for maintenance personnel and compliance with noise-level regulations.

Key Findings:

- Initial analysis revealed inadequate airflow coverage, resulting in hot spots where temperatures exceeded critical thresholds by 10–15%.

- Based on our recommendations, the team redistributed the server hardware to balance heat loads more effectively.

- We proposed a redesign of the HVAC system, including the addition of a bi-directional unit to cool a thermally isolated corner of the room.

- Post-redesign simulations showed that all monitored zones were maintained at temperatures 5–10% below critical thresholds, even under partial system failure.

Outcome:

TotalSim’s CFD-driven insights directly informed a more resilient and efficient HVAC design, increasing the client’s confidence in their bid. By identifying and resolving key thermal and acoustic issues early in the design process, we helped reduce risk, enhance reliability, and ensure thermal compliance—key factors for modern data center operations.

Learn more about the ways TotalSim can help you overcome your aerodynamic challenges

*What is CFD?

Computational fluid dynamics (CFD) is a branch of fluid mechanics that uses computer numerical analysis and data structures to analyze and solve problems that involve fluid flows, typically solved on large supercomputers. Fluid mechanics plays a significant role in the engineering process when developing new designs. Analyzing the aerodynamic and thermal qualities of a product using experimentation is a well-established approach however experimentation can be costly, limiting, time-consuming, and difficult to execute especially on a large scale. Progression of computing power has allowed the field of CFD to prosper acting as a complement to physical testing and in some cases replacing it. CFD is the science of predicting fluid flow, heat transfer, mass transfer, chemical reactions, and other flow properties by solving governing fluid flow equations using numerical methods. Across the industry, CFD is routinely used to drive product development, troubleshoot issues, study and optimize new designs and concepts, and map performance. CFD methods are heavily used across many disciplines with motorsports being a leading proponent.