As global reliance on digital infrastructure grows, data centers have become essential components of modern operations. From storing critical business data to supporting real-time cloud services, these facilities must maintain constant uptime and thermal stability. However, managing the heat generated by high-density hardware presents a significant engineering challenge—especially when systems need to remain operational even in the event of HVAC failure.

Faced with these demands, a building services and construction contractor, in collaboration with a design partner, sought to validate and optimize the cooling system of a new state-of-the-art data center. TotalSim was brought on board to provide computational fluid dynamics (CFD) expertise using Siemens’ STAR-CCM+ software, with the goal of enhancing both performance and resilience.

Understanding the Challenge

The proposed data center design needed to accommodate high heat loads while ensuring that no part of the enclosure exceeded critical temperature thresholds. More importantly, the system needed to demonstrate reliability under failure scenarios, where one or more HVAC units might be offline. Achieving this required detailed airflow modeling, failure simulation, and system optimization.

TotalSim’s Simulation-Driven Approach

1. Airflow Modeling and Baseline Analysis

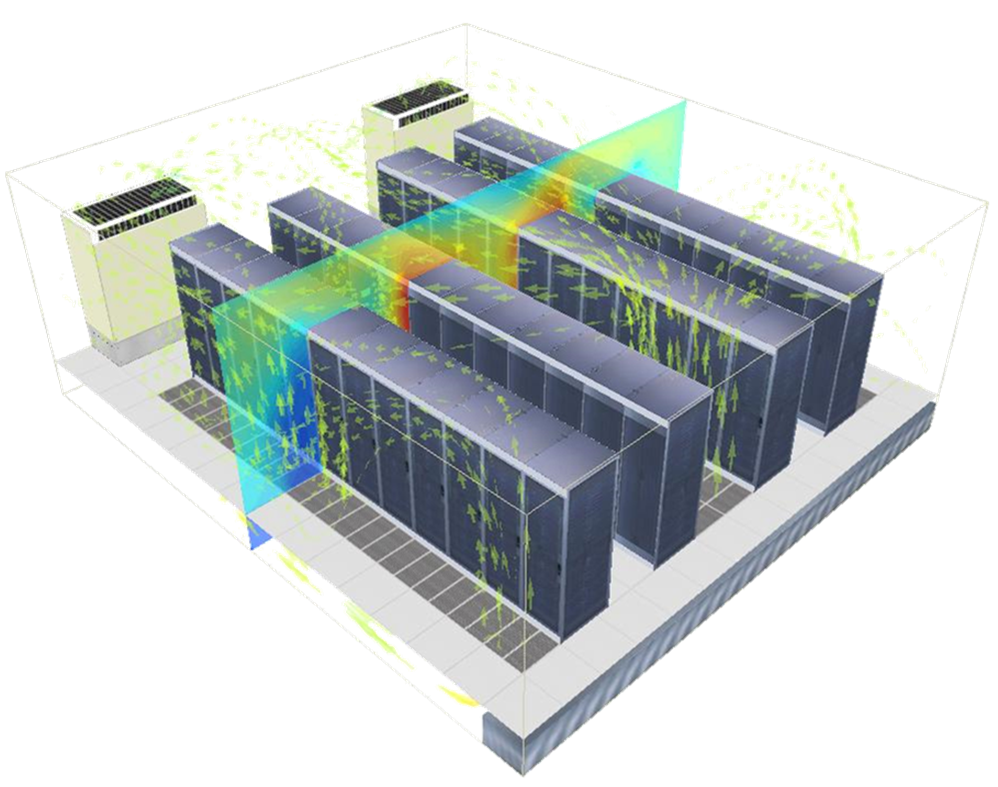

TotalSim began by creating a detailed CFD model of the initial data center layout using STAR-CCM+. Special attention was given to the placement of server racks and exhaust flows, as well as structural elements that might obstruct airflow. This simulation provided a baseline understanding of how air circulated throughout the enclosure under normal operating conditions.

2. Failure Mode Analysis

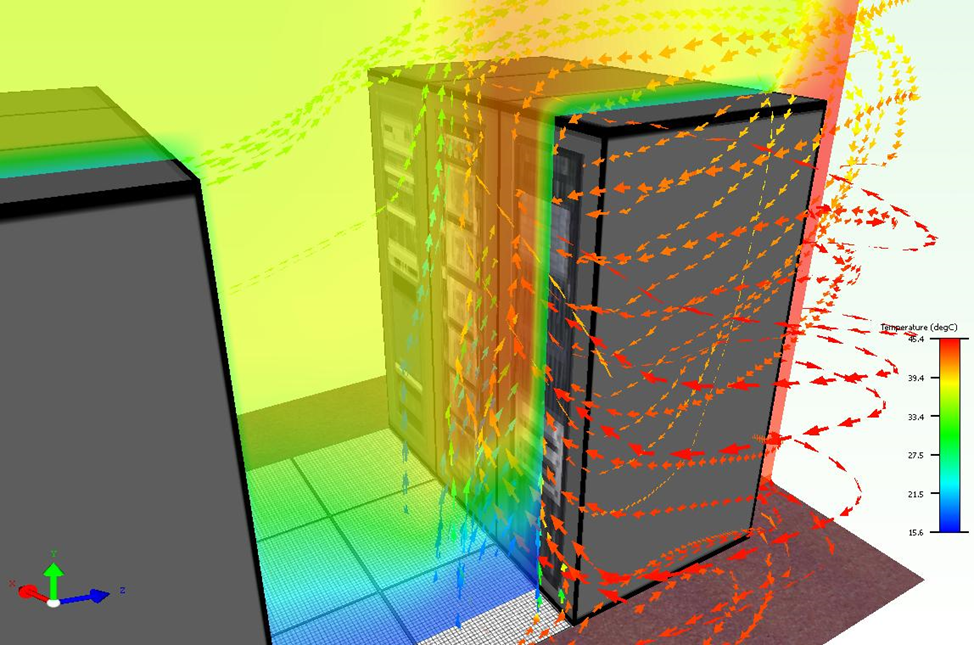

To assess the resilience of the system, TotalSim ran simulations that systematically disabled various HVAC units to replicate potential failure scenarios. These tests revealed multiple zones where temperatures spiked 10–15% above acceptable limits, identifying vulnerabilities in the original design.

3. Design Optimization

Armed with simulation data, the team recommended key changes to address these issues. These included angling HVAC vanes to better direct airflow and redistributing server hardware to balance thermal loads more effectively. A significant modification was the introduction of a bi-directional HVAC system to resolve persistent cooling deficiencies in a corner of the room.

4. Acoustic Assessment

In addition to thermal performance, TotalSim used Siemens’ Ray Acoustics Modeling to analyze noise propagation from hardware fans. This step ensured that the design also met acoustic performance expectations—an important consideration for onsite personnel and compliance.

Measurable Results

The revised design showed substantial improvements. Post-simulation results indicated that all monitored areas now remained 5–10% below the critical temperature threshold, even during simulated HVAC failures. The new layout not only eliminated previous hotspots but also enhanced overall airflow efficiency, contributing to a more robust and future-ready facility.

A Stronger Bid, A Smarter Design

TotalSim’s simulation-led analysis enabled the contractor to present a highly resilient and optimized design, strengthening their position during the competitive bidding process. The project demonstrated how CFD can reduce design risk, improve system performance, and deliver data-backed confidence in complex engineering environments.