In the world of professional and Olympic cycling, fractions of a second can be the difference between gold, silver, bronze or not placing at all. Over the last decade plus, the sport has seen an increased focus on applying technology and engineers to reduce drag and rolling resistance. This means less energy is required from the athlete to go a given distance, which makes it possible to achieve higher speeds and quicker race times for the same or less energy output. One large component of the forces the athletes have to overcome is aerodynamic drag – both on the athlete themselves and on the equipment. For the athlete, it’s about finding the best compromise of riding position and power output, while equipment work is done to improve the bike frame, handlebars, wheels and tires, as well as the rider’s suit, helmet, shoes and socks.

Time Trials and Road Races: Mastering Aerodynamics

At the extreme, the emphasis on aerodynamics and drag reduction can be seen during the Time Trial (TT) races. The rider is in a full tuck position with elbows and forearms close together leaning on special TT handlebars, full aero suits with covers over shoes and socks, along with special helmets (which are increasingly looking quite comical!). On the TT bikes, you’ll typically see full disk wheels in the rear and deep front rims. The bike frames and “tubes” themselves (which are now not close to round and made exclusively of carbon composites) are designed to be as low drag as possible. Even the tire profiles are designed to reduce drag as well as low rolling resistance over the ground. You see similar bikes for Triathlon and for track (velodrome) racing although each are slightly different because of the rules allowed and the exact nature of the racing itself. This is actually quite cool for engineers involved (and athletes) as it means optimizing each component of the setup for each specific discipline.

Some of the new TT helmets from our friends at Giro!

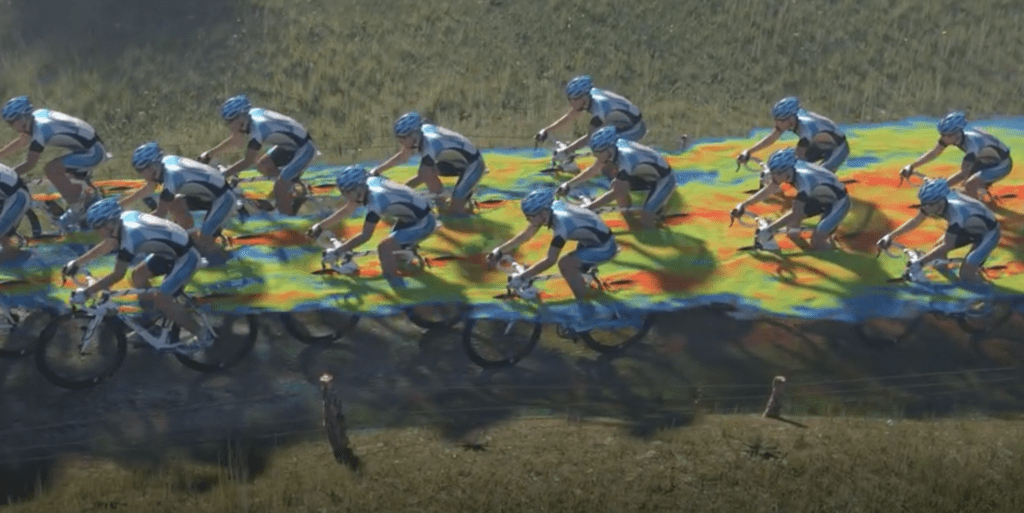

Switching to the road race (races like the Tour de France or other shorter events) you can see how important aerodynamics is by watching the cyclists ride in a large pack called a ‘peloton’. By sitting behind another rider (called ‘sitting on the wheel”), the following rider is shielded from the air and riding in the wake of the leader. Even this seemingly small reduction in effort by the trailing rider is hugely significant over the course of a day or weeks in a race like the Tour. In a sprint to the finish you’ll see riders using this reduced drag to accelerate in the wake and then slingshot around the leader. We made a video of a CFD simulation of a peloton of cyclists to try to illustrate the wake and its significance.

To achieve all these optimized designs, national teams (USA Cycling, British Cycling, etc.) and pro teams (think: Tour de France), along with the various part manufactures, have increasingly been doing more and more controlled testing using combinations of tools including wind tunnels, computational fluid dynamics (CFD) simulations, on-bike data instrumentation and even instrumenting full indoor or outdoor test tracks.

Real-Life Applications

TotalSim has a rich history in cycling aerodynamics though our UK counterparts TotalSim Ltd, which has worked on these programs for almost two decades. In fact, the great results for British Cycling at the 2012 London games was recognised by Dr. Rob Lewis, TotalSim Ltd founder, receiving an OBE from the Queen for their efforts related to UK Sport.

The TotalSim group in the UK has expanded on this work by creating a dedicated Sports Engineering Hub at Silverstone (SSEH), which includes a sports specific wind tunnel, a colocated ‘skin suit’ design and manufacturing company Vorteq Sports. The wind tunnel is currently being used by several top level pro and National teams, manufactures and Vorteq has been supplying Olympic and Pro teams with custom suits and development programs.

Harnessing the Power of CFD

CFD is another tool that is increasingly being leveraged alongside this wind tunnel testing. The simulations have been used for decades now to ‘see the flow’ and look for areas of possible development highlighting flow features that could indicate potential drag reductions. Skilled use of the entire suite of aero tools while at the same time, being able to leverage the strengths of each is key to a successful program. Any one tool, be it wind tunnel or CFD, used in isolation is generally not the best solution. Some of the details of the airflow, such as boundary layer capture and transition, are still extremely challenging to model in CFD but as the software (such as STAR-CCM+ which TotalSim resells) and hardware (such as GPU acceleration) evolve to allow more accurate and detailed simulations, the lines between physical and virtual simulation blur more and more.

Most of the teams at the top level are working with each athlete individually to find the right combinations of equipment and positions that they, of course, hope will yield the best results for the individual, and ultimately the team together. In fact, for some of the suit and helmet work, Vorteq even goes to the level of 3D printing full size mannequins of select athletes to do the development work in the wind tunnel.

So when you are watching the Paris cycling events this month, think about all the effort and engineering that goes into the results, and keep an eye out for some trick looking helmets, interesting features on skin suits and try to compare each rider’s choice for position and see what you think. Of course, it’s a sport so it can always come down to some luck, unforeseen issues like flat tires or weather…but that’s the fun and the challenge of it!

Here is Lilly Williams, USA Cycling Track cyclist, recently talking about the crazy helmets and aero testing at Silverstone: