Electronics & Battery

TotalSim Electronics & Battery Industry CFD Solutions

Totalsim’s dedicated solutions for the electronics & battery industry enable you to account for all aspects of plane performance. We’ve used CFD simulation to streamline the complex process of modeling the physics of graphics card, thermal management and fan location optimization. We easily visualize results helping you to evaluate and improve your designs. Explore our electronics & battery capabilities below.

Battery Electro-Thermal Modeling

Battery Simulation Module

Li-Ion Battery Cell Model

Totalsim Workflows in Electronics and Battery as a design tool:

TotalSim's motor-sport technology has been borrowed for the construction of electronics and battery, workflows that require the use of complex models to calculate the voltage performance of a battery cell or its behavior using methods with computational fluid dynamics. TotalSim's workflows create a digital twin to the battery process. Our technology was born in the automotive F1 race track and can be employed to address critical electronic circuit & battery issues.

The following workflow capabilities provide an overview of what can be accomplished when using our StarCCM+ workflows for the most complex challenges that necessitate CFD technology.

Benefits We Provide

Working with virtual modeling and simulation of fluid flows allows you to accelerate your design process using software such as Star-CCM+ or OpenFOAM. This reduces the number of physical prototypes and testing, while still evaluating all necessary conditions. Our engagement ranges from CFD consulting, to training, to customized workflows to meet your specific needs.

Explore Our Electronics and Battery Capabilities

Electronic Circuits

Multi-Part Solid: Graphics Card Cooling

Our proprietary workflow provides an automated methodology that helps our customers analyze multipart solid heat transfer in a single region.

Our workflow does the following:

- Calculate Convective Heat Transfer Inside the Case

- Calculate Conductive Heat Transfer Between the Solid Parts in Contact, like the Components Inside the Graphics Card

- Apply Different Heat Sources on Parts in A Single Region

- Represent Fans by Fan Interfaces

- Calculate the Thermal Profile through the PCB Layers

Graphics Card Cooling

Our proprietary workflow provides an automated methodology that allows us to help our customers calculate the drive of fans flow inside the case. This cools the card and calculates the following:

- Optimized Position of Fans that Cool Electronic Components

- Impact Fans have on Removing Heat

-

Conduction in the Solid Components of the Graphics Card and the Fans

-

Diffusion and Forced Convection in the Enclosed Air

- Multiple Arrangements and Determine Best Performance

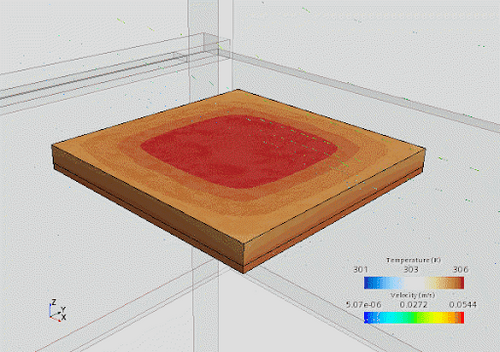

Electronics Cooling Toolset: Natural Convection JEDEC

TotalSim's workflow uses StarCCM+ to help our customers meet JEDEC thermal standards with devices that rely on natural convection only.

The electronics cooling toolset includes a method for estimating cooling due to:

- Conduction in the Solid Components of the Test Rig, the Chip Package and the Chamber.

- Diffusion, Natural Convection and Radiation in the Enclosed Air

Battery Simulation

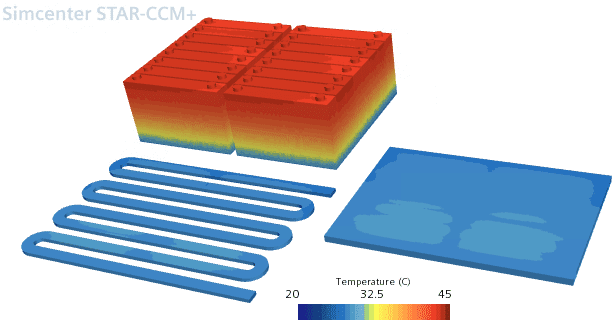

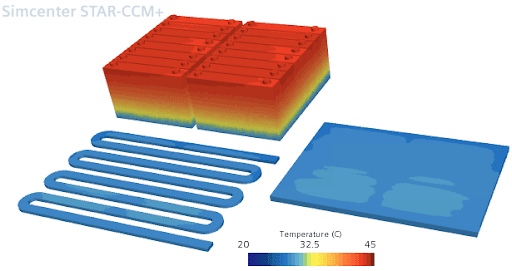

Battery Electro-Thermal Modeling

Our battery workflow helps us ensure your battery pack operates in a safe temperature range.

Our workflow helps you to do the following:

- Perform an Electro-Thermal Simulation Where a Tight Coupling Between the Electrical Behavior of the Cell and its Thermal Response is Operated

- Manage Situations Such as Fast Charge or Drive Cycles in Various Conditions

Battery Module: Cell Thermal Analysis

Our cell thermal analysis workflow allows us to help clients simulate battery heat generation that occurs during a certain period of time of a discharge cycle. Our workflow accomplishes the following:

- The Addition of More Cells in A Series to Investigate the Impact of Heat Generation

- Simulation Using A Voltage Plot to Monitor the Battery Discharge During the Cycle

- Results Display How Battery Heat Generation is Distributed on the Battery Cells

For Cylindrical Cells:

- Cylindrical Cells are Connected in Series and are Discharged for A Period of Time With A Certain Load in Amperes

- Configuration of Cylindrical Battery Cells Using A Staggered Configuration with Uniform Spacing

- Results Model the Heat Generation in the Battery and the Air Flow in the External Casing

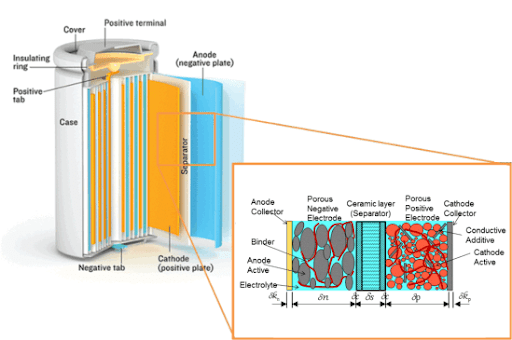

Li-Ion Electrochemistry Analysis

Our Li-Ion Battery Cell workflow allows us to ensure that your Li-Ion Battery Cell design operates efficiently at the microscale level.

Our proprietary workflow allows us to help you do and identify the following:

- Microstructure of Porous Battery Electrodes

- Determine Li-Ion/Salt Concentration in the Active Materials

- Electric Current Density

- Identify High Current Density at Locations of Interest