3D Scanning and reverse engineering services

Improve performance with TotalSim’s end-to-end reverse engineering solution.

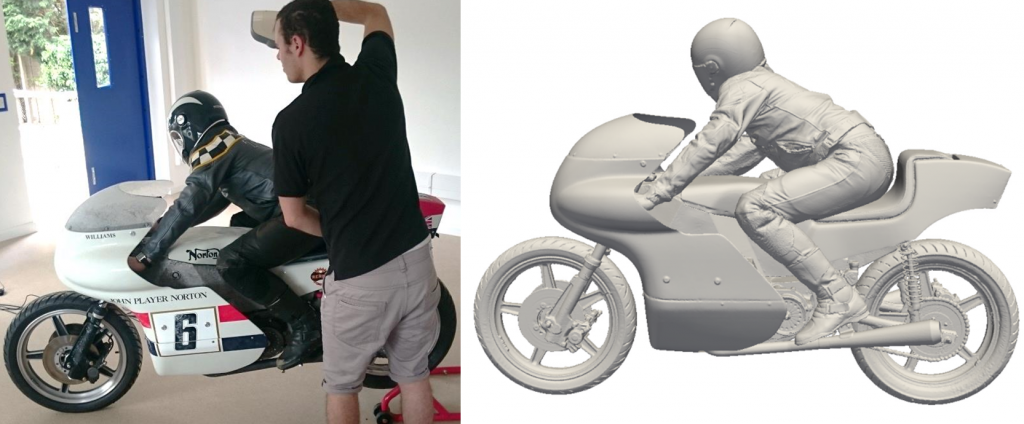

Reverse engineering of an existing prototype or model can help you uncover issues with particular features and parts of a vehicle, aircraft, ship or even industrial machinery to enhance overall aerodynamic performance. TotalSim’s Reverse Engineering service integrates 3D scanning with CFD technology to help you get fast, affordable and accurate results for all work conditions or environments.

The 3-D Scanning Process

⇒

Start with any part you want to scan

⇒

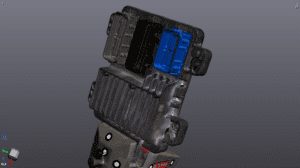

We scan that part using state of the art hardware and software - capturing both the surface and textures

⇒

With the files we provide, you can design your dream!

On-Site or Remote 3D-Scanning

Whether you want to ship your parts, bring your project to us or have a fully equipped laser scanning technician come to you, TotalSim can flexibly accommodate your project needs.

Scan-To-CAD

Laser scans can be delivered in .STL, .OBJ, .X3D, X3DZ, .dae, .fbx, .ma or wrl file formats to import into Solidworks, Fusion360, or other CAD programs.

3D - Scanning for Custom Car Building

Designing and building professional grade custom parts in your home garage has never been more accessible with the advances in 3D-printing, rapid prototyping and mail-delivery CNC machining services.

Leverage the same people working with Nascar and iRacing to help bring your ideas and designs to life.

Design and Customization

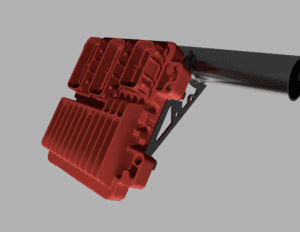

Doing an engine swap and want to design your own mounts?

Wondering how to design your own body kit?

Will that turbo really fit there?

You can deliver your projects to us for scanning or we can come directly to you.

Manufacturing and Prototyping

Designing and building parts from scratch is tough, especially when you want to start manufacturing them yourself.

Starting your project ideas with highly accurate 3D models saves you the time of having to manually measure and model technical parts and surfaces.

Performance Optimization

Our team works with professional racing teams and major OEM's every day.

We provide everything from basic raw scan files, to watertight models for 3D printing, to conducting an aerodynamic analysis and optimization of your project.

In late May, our own Ben Cantrell had the opportunity to fly out to Oregon and meet with Kyle Kuhnhause, custom hot rod builder and a SEMA Battle of the Builders finalist. The purpose of his trip was to assist with 3D-scanning for a 66 Corvette Kyle is currently working on. Ben used TotalSim’s Creaform 3D white light scanner to reverse engineer several parts and surfaces. These scans will help generate new products and custom solutions in the future and over the past few weeks Kyle has been turning the data into manufacturable components.

TotalSim's Reverse Engineering capabilities include:

TotalSim uses Creaform's 3D scanners to create a portable, fast and highly-accurate scanning solution for any of your simulation needs.

Metrology-grade Measurements

Receive accuracy of up to 0.030 mm (0.0012 in), resolution of up to 0.050 mm (0.002 in), highly repeatable measurements and a traceable certificate.

No Rigid Set-up Required

Optical reflectors are used to create a reference system "locked" to the part. Use dynamic referencing to move the object how you want during scanning sessions without impacting data acquisition quality or accuracy.

Self-positioning

No external tracking or positioning device is required since the HandySCAN 3D scanner is a data acquisition and positioning system.

Simulate Surface Data

Leverage our automated simulation meshing process with your surface data to get fast, accurate results.

Reliable

Consistent and repeatable results across all work conditions or environments.

Why Use TotalSim for Reverse Engineering?

FLEXIBILITY

Whether we produce a scan for you or you already have scanned product data, we can begin the simulation process straight from your point cloud.

REPEATABILITY

No matter your work conditions or environments, you’ll receive consistent and repeatable results to achieve your specific reverse engineering goals.

ACCURACY

TotalSim uses advanced surface creation and repair methods to ensure your surface representation is generated quickly and accurately.

AFFORDABILITY

Reverse engineering doesn’t have to be expensive. We’ve combined our scanning and CFD experience to give you an affordable, yet high quality reverse engineering solution.

Laser Scanning for Historical Preservation

By creating accurate 3D models and records, laser scanning can help ensure that important historical sites are preserved for future generations to enjoy and learn from.

Preservation

3D - scanning can help preserve historical monuments or structures by creating highly accurate 3D models that can be used to identify deterioration.

Any changes, wear or damage can be detected early by regularly scanning the monument or structure.

This allows for repairs and preservation to be completed with ease.

Restoration

By creating highly detailed and accurate 3D models of historical items, restoration teams can recreate missing or damaged features.

This ensures the restored pieces match as closely as possible to the original.

Research and Documentation

3D - scanning can be used to create virtual tours or educational materials. This allows people to explore historical items in detail, even if they're unable to visit in person.

TotalSim's scanning services are able to accurately capture all textures and colors, whether it's carbon fiber, or a rich piece of history.

Find out more about our flexible, tailored 3D-scanning services.

"*" indicates required fields